It is possible to apply paints of any color, finish, and gloss on galvanized steel.

This operation, which obviously comes at a higher cost than just galvanizing, results in an even greater protection and thus a longer lifespan. The two corrosion-resistant treatments work synergistically, and the protection lasts far beyond the sum of the individual lifespans of each treatment. In economic terms, this results in significant benefits, as the useful life of the product is extended without requiring maintenance.

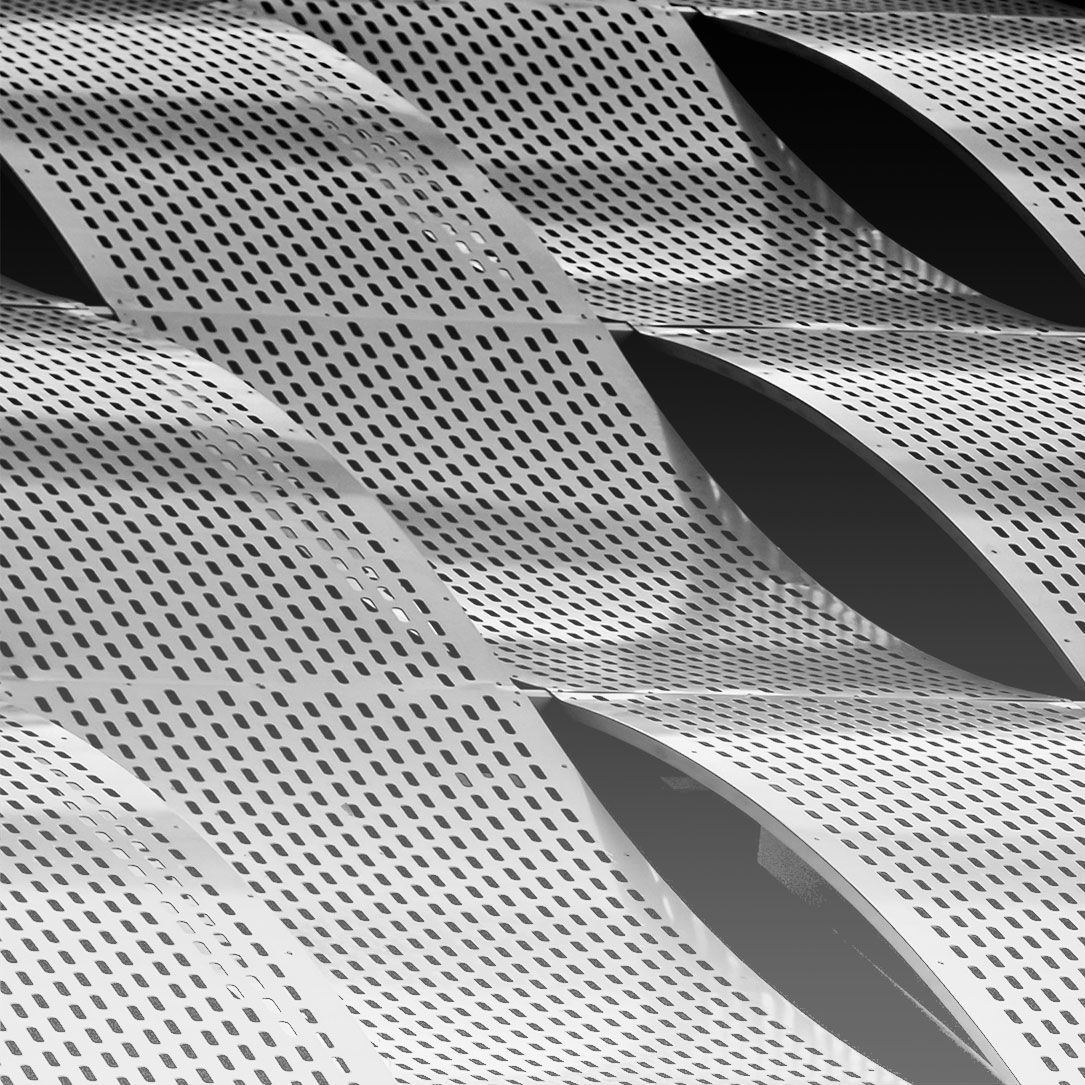

Additionally, the environmental sustainability impact is complemented by an aesthetically superior finish suitable for urban and metropolitan contexts.

The painting cycle uses certified polyester and epoxy-polyester powder coatings from leading manufacturers, with quality control and polymerization in a constant temperature oven.

Technical Characteristics of the Coating with Relevant Standards:

– Average Thickness: 70 / 80 microns;

– Bend Test (Cylindrical Mandrel): UNI EN ISO 1519;

– Bend Test (Conical Mandrel): UNI EN ISO 6860;

– Cupping Test: UNI EN ISO 1520;

– Cross Hatch Test: UNI EN ISO 2409:2007 Grade 0;

– Moisture Resistance: UNI EN ISO 6270-1:2001 – UNI EN ISO 6270-2:2005.

Weather Resistance Test on RAL Sample at 80 Gloss:

– At 0 hours: 80 gloss;

– After 12 months: 80 gloss (film unchanged);

– After 24 months: 70 gloss;

– After 36 months: 60 gloss.

Corrosion Resistance:

– Neutral Salt Spray Resistance Test: UNI EN ISO 9227 (Salt spray test for 960 hours)

Powder Coating Cycle with Thermosetting Polyester Powders on Hot-dip Galvanized Material According to UNI Standards Currently in Force:

– Phosphatizing and mordant flow-coating to remove oils and general dirt, for 5 minutes at 60°C with water and product;

– Rinsing with network water for 5 minutes;

– Acid phosphoric pickling for 5 minutes at 50°C;

– The flow coating rinses with mains water at room temperature for 3 minutes;

– Passivation flow-coating with chrome-free zirconium at 40°C for 5 minutes;

– The flow coating rinses with mains water at room temperature for 3 minutes;

– final coating by flow with demineralised water at room temperature for 5 minutes;

– oven drying at 130 / 150 °C;

– application of the polyester powder TGCI free in cabin with n. 10 guns automatic up to 80/90 micron thickness

– curing in a ventilated oven at a constant temperature of 190°C for a minimum time of 50 minutes, until the paint film is completely cured (following the indications given on the technical data sheet of the varnishing product).

The color chosen by the customer is applied in accordance with UNI EN ISO 2409, class 1-2808 – DIN 53132 – ASTM B117.